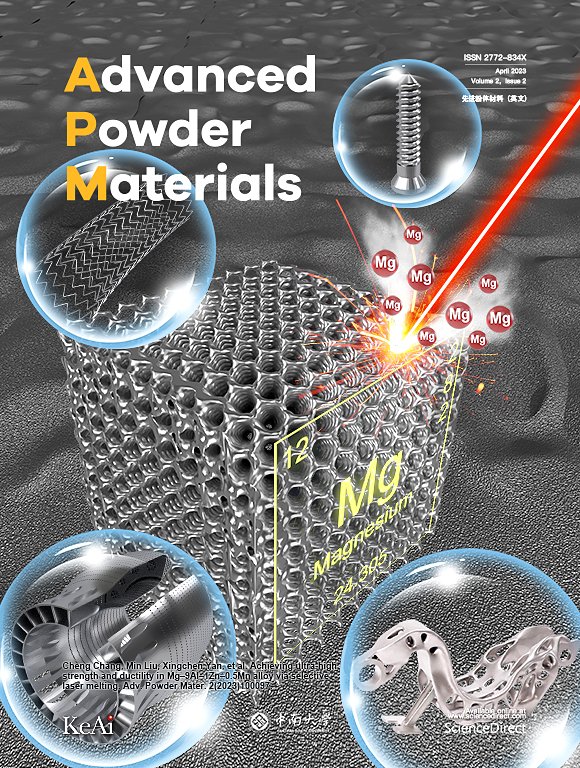

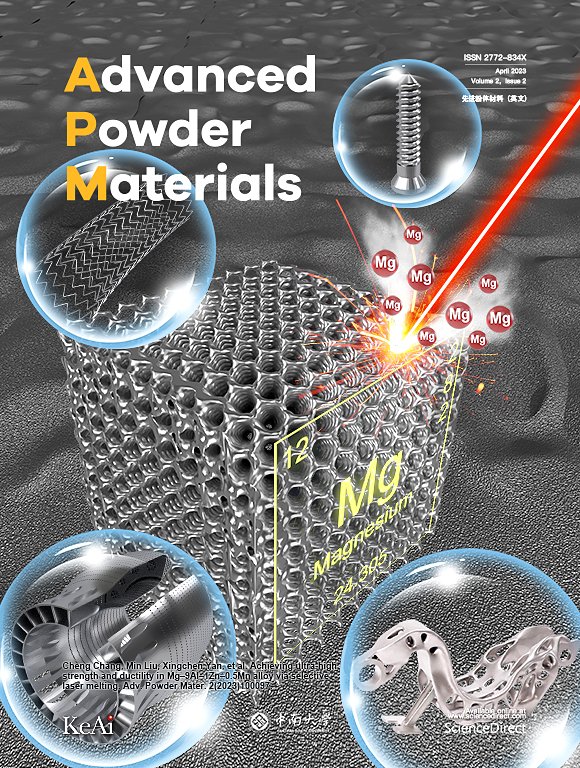

Journal Name: Advanced Powder Materials

Overview

In today’s fast-paced industrial landscape, Advanced Powder Materials have emerged as a cornerstone of innovation, playing a critical role in sectors ranging from aerospace and automotive to electronics and healthcare. These finely engineered powders are tailored for high-performance applications, offering unique properties that surpass traditional materials in strength, durability, conductivity, and versatility.

What Are Advanced Powder Materials?

Advanced Powder Materials are engineered powders composed of metals, ceramics, polymers, or composites. Unlike conventional powders, they are designed with precision at the micro- and nano-scale to deliver specific mechanical, thermal, electrical, or magnetic properties. These materials are crucial in processes like additive manufacturing (3D printing), powder metallurgy, thermal spraying, and coating technologies.

Some commonly used advanced powders include:

-

Metal Powders (e.g., titanium, aluminum, stainless steel)

-

Ceramic Powders (e.g., zirconia, alumina, silicon carbide)

-

Alloy Powders (e.g., Inconel, cobalt-chrome)

-

Nanopowders with enhanced surface area and reactivity

Key Applications and Benefits

The versatility of advanced powder materials enables their application in a wide range of high-tech industries:

-

Aerospace & Defense: Lightweight yet durable powders are used in aircraft components and turbine blades, improving fuel efficiency and performance.

-

Automotive: Powder metallurgy helps manufacture complex parts with minimal waste, enhancing sustainability and cost-effectiveness.

-

Electronics: Conductive and magnetic powders are critical for semiconductors, batteries, and electromagnetic shielding.

-

Medical Devices: Biocompatible powders like titanium and hydroxyapatite are used for implants and prosthetics.

The benefits of using advanced powder materials include:

-

Enhanced Material Performance: Improved strength, heat resistance, and wear resistance.

-

Precision Manufacturing: Ideal for producing intricate and lightweight parts through additive manufacturing.

-

Sustainability: Lower material waste and energy use compared to traditional manufacturing methods.

Emerging Trends and Innovations

With ongoing advancements in nanotechnology, materials science, and AI-driven material design, the future of advanced powder materials looks promising. Key trends include:

-

Smart Powders: Engineered to respond to environmental changes or self-heal.

-

Green Manufacturing: Eco-friendly powders made from recycled or sustainable sources.

-

Advanced Sintering Techniques: Enabling faster, cleaner, and more precise part production.

As industries push the boundaries of innovation, demand for high-performance materials that support lightweight design, energy efficiency, and reliability continues to grow. This makes advanced powder materials an essential part of the modern manufacturing ecosystem.

About

Advanced powder materials are at the forefront of innovation in materials science, reshaping the way industries approach manufacturing, product design, and performance optimization. These finely engineered powders possess unique physical and chemical properties that make them indispensable in a wide range of high-tech applications, from aerospace and automotive to electronics and biomedical engineering.

What Are Advanced Powder Materials?

Advanced powder materials refer to finely divided solid particles engineered at the micro or nano scale. These powders are often composed of metals, ceramics, polymers, or composites and are designed to meet specific mechanical, thermal, electrical, or chemical requirements. Through precise control of particle size, shape, distribution, and composition, these materials deliver exceptional performance characteristics compared to traditional bulk materials.

Applications Across Industries

One of the most transformative uses of advanced powder materials is in additive manufacturing (3D printing). Metal powders such as titanium, aluminum, and stainless steel are used to create lightweight, high-strength components with complex geometries—ideal for aerospace and automotive applications. Similarly, ceramic powders like zirconia and alumina are utilized for their heat resistance and biocompatibility in dental and medical implants.

In the electronics industry, nanopowders are essential for producing high-performance batteries, conductive inks, and magnetic components. Energy storage devices, including lithium-ion batteries and supercapacitors, rely on powder-based electrodes that offer increased surface area and improved conductivity.

The pharmaceutical and cosmetic sectors also benefit from powder technology. Microencapsulated powders are used to enhance drug delivery and prolong shelf life, while ultra-fine powders in cosmetics improve texture and application efficiency.

Key Advantages of Advanced Powder Materials

-

Customization: Advanced powders can be engineered to possess specific traits, such as high thermal stability, corrosion resistance, or magnetic properties.

-

High Surface Area: Nanopowders offer increased surface reactivity, which is beneficial in catalytic and chemical applications.

-

Lightweight and Strong: Metal matrix composites made from powder materials can significantly reduce weight while maintaining strength, ideal for aerospace and defense.

Future Trends and Innovations

As demand for sustainable and high-performance materials grows, research into green manufacturing techniques and recyclable powder materials is gaining momentum. Innovations in powder metallurgy, such as spark plasma sintering and hot isostatic pressing, allow for the creation of near-net-shape components with minimal material waste.

Nanotechnology is another driver in the evolution of advanced powder materials. With enhanced control at the atomic level, manufacturers can create next-generation components for quantum computing, smart sensors, and nano-medicine.

Scope

In today's fast-paced, technology-driven world, advanced materials are transforming how industries operate. Scope Advanced Powder Materials stands at the forefront of this revolution, offering high-performance powders engineered for precision, strength, and efficiency. These materials are essential across sectors like aerospace, automotive, electronics, energy, and medical devices, providing the foundation for next-generation manufacturing and innovation.

What Are Advanced Powder Materials?

Advanced powder materials are finely engineered particles made from metals, ceramics, or composites. Designed for specific performance characteristics, these powders are used in additive manufacturing (3D printing), thermal spray coatings, metal injection molding, and sintering processes. The unique properties of advanced powders—such as controlled particle size distribution, purity, and flowability—ensure optimal performance in high-stress environments.

Scope Advanced Powder Materials are developed using cutting-edge technologies like gas atomization, plasma atomization, and chemical precipitation. These methods ensure uniformity, high purity, and tailored material properties to meet the demanding requirements of modern manufacturing.

Applications of Scope Advanced Powder Materials

-

Aerospace and Defense:

Lightweight, high-strength alloys such as titanium and nickel-based powders are crucial in producing aircraft components, turbine blades, and satellite parts. Scope's powders enhance durability while reducing weight, leading to improved fuel efficiency and performance. -

Automotive Industry:

With the push toward electric vehicles (EVs), thermal management and lightweight components are more important than ever. Advanced powder materials from Scope enable precision manufacturing of parts like battery components, gear systems, and structural frames through additive manufacturing. -

Medical Devices:

Biocompatible materials like titanium and cobalt-chrome powders are used in producing implants, surgical tools, and dental prosthetics. Scope ensures these powders meet stringent medical-grade standards for safety and performance. -

Energy Sector:

From solar energy systems to nuclear reactors, high-performance powders are vital in energy production. Scope’s powders are designed for extreme conditions, offering excellent thermal resistance and corrosion protection. -

Electronics and Semiconductors:

With the demand for miniaturized components, advanced powders facilitate precise manufacturing of connectors, sensors, and heat sinks with superior conductivity and strength.

Why Choose Scope Advanced Powder Materials?

-

Custom Solutions: Scope offers tailored powder formulations to meet specific client needs across various industries.

-

Superior Quality: Advanced quality control ensures consistency in particle size, shape, and purity.

-

Sustainability Focus: Scope prioritizes environmentally responsible manufacturing processes, aligning with global sustainability goals.

-

Global Reach: With a robust distribution network and technical support, Scope serves clients worldwide, providing fast, reliable service.

Future Outlook

The market for advanced powder materials is rapidly expanding, driven by technological advancements and growing industrial demand. Scope is continually investing in R&D to develop next-generation materials that push the boundaries of performance, efficiency, and sustainability.